New precision machines arrive at TK

Continuing a tradition of steady and continuous investment, two precision machine tools

have arrive at TK: The first is an ultra precision 8400 CNC moore Jig Grinder, rebuilt for us

in the US by 2SQ Industrial supply Inc. It is controlled by a Fagor CNC controller, operating

on a 5 axis basis (X,Y,Z and U & C on the grinding head).

Moore 8400

The Z axis feed has been modified to give full Z-axis control, turning the Jig Grinder

into an ultra-precise sub-micron resolution milling machine.

Huron K2X10

The second machine is a Huron K2X10 1000mm by 800mm table-movement high speed milling

machine with a Heidenhain ITNC530 control. Constructed as a gantry machine, and with

heat shrink balanced tooling, we are hoping that it will allow us to make, for example,

sub-10u RMS mirrors at large sizes.

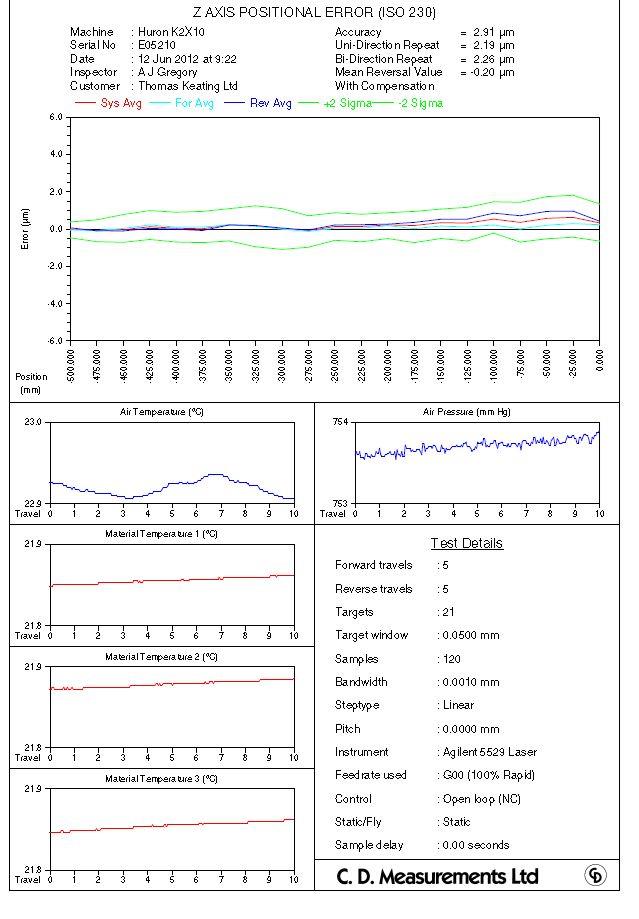

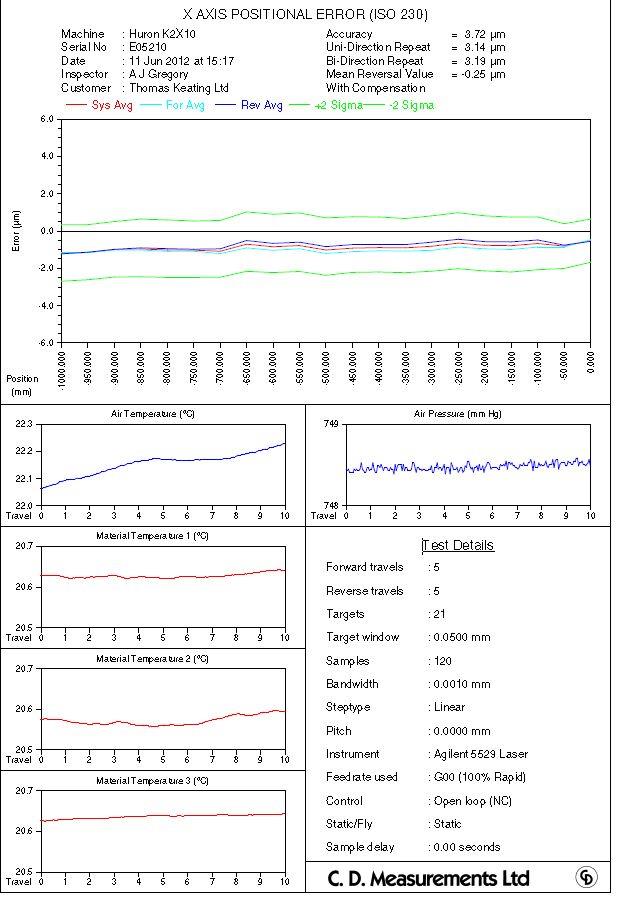

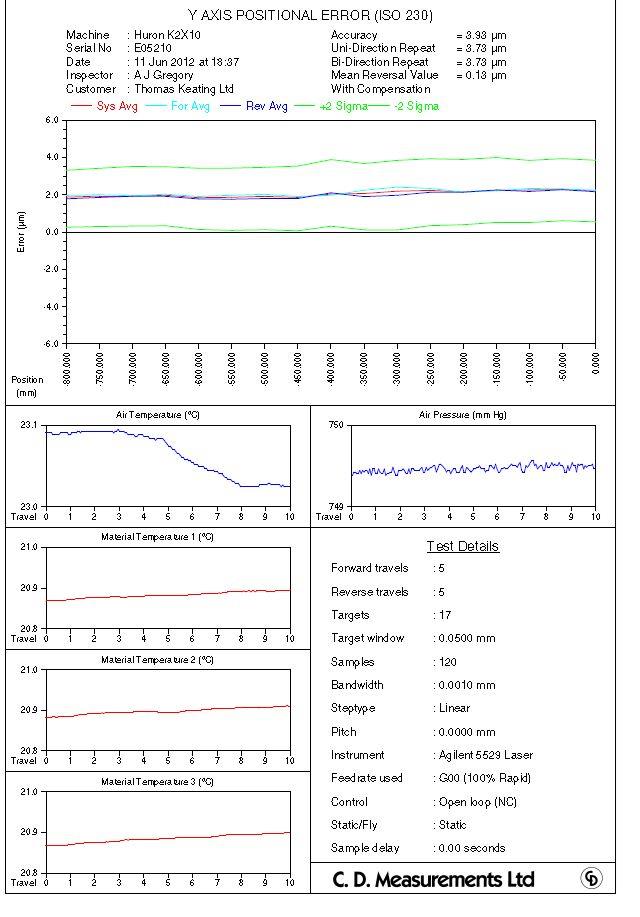

The linear scales of the Huron have been calibrated using a laser interferometer to give the

following results

In X, 3.7u

In Y , 3.93u

and in Z, 2.91u